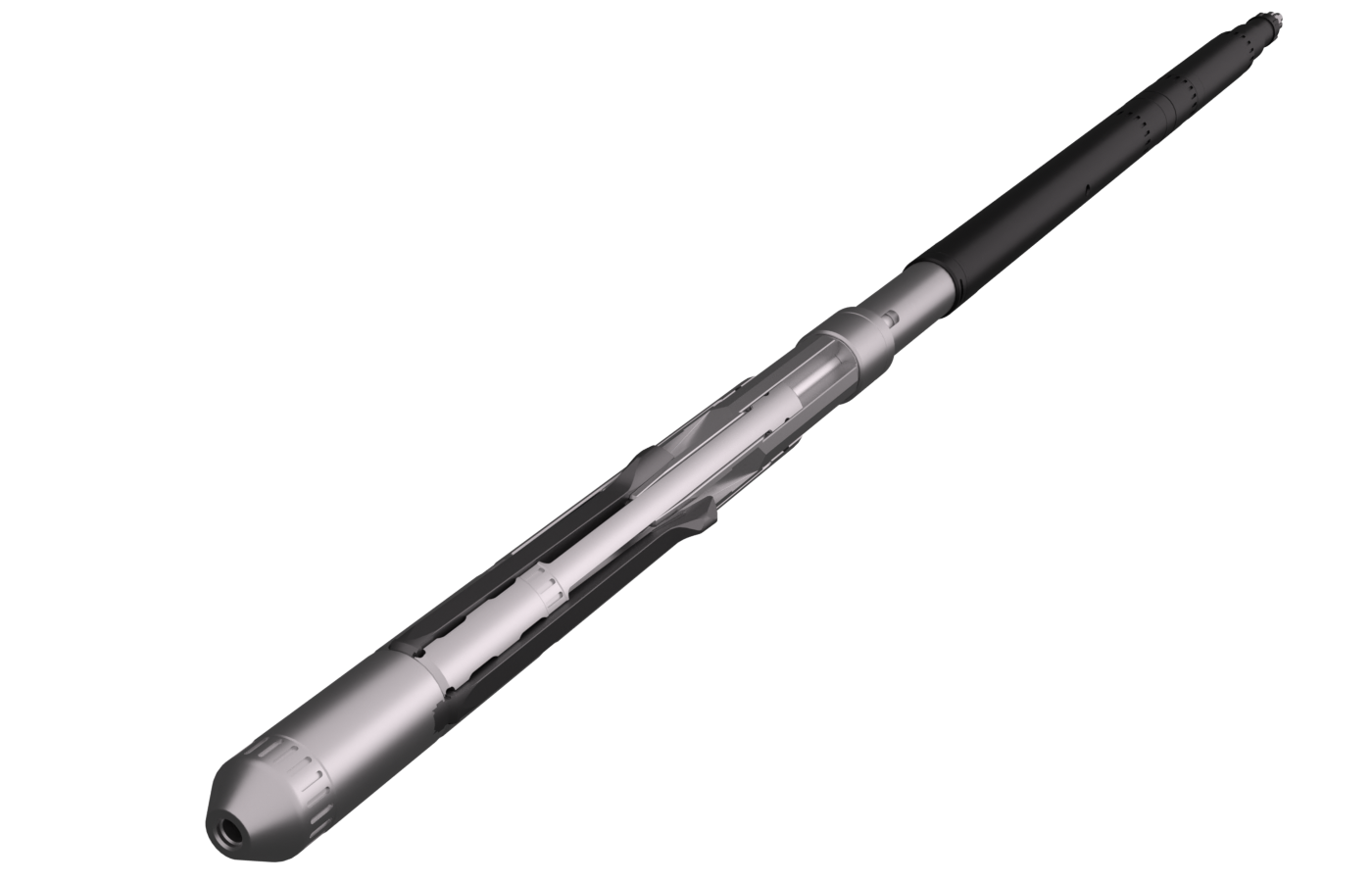

TorcDesperado

High force linear actuator

The TorcDesperado is a base platform converting the rotational force of the EMT into raw linear or axial force. This significantly enhances push and pull forces available in a Wireline system. The control and granularity of the exerted forces provided by the EMT and the TorcMethod increases your success rate, while bringing down both risk and turnover time.

The system is capable of providing forces of 220 000 lbs, or 100 Metric tons, accommodating a range of applications and tools. You can open collapsed tubulars of any geometry, do local expansion for anchoring tubular plugs in your P&A operations, do shifting and dimpling operation, and much more.

.jpg)

.jpg)

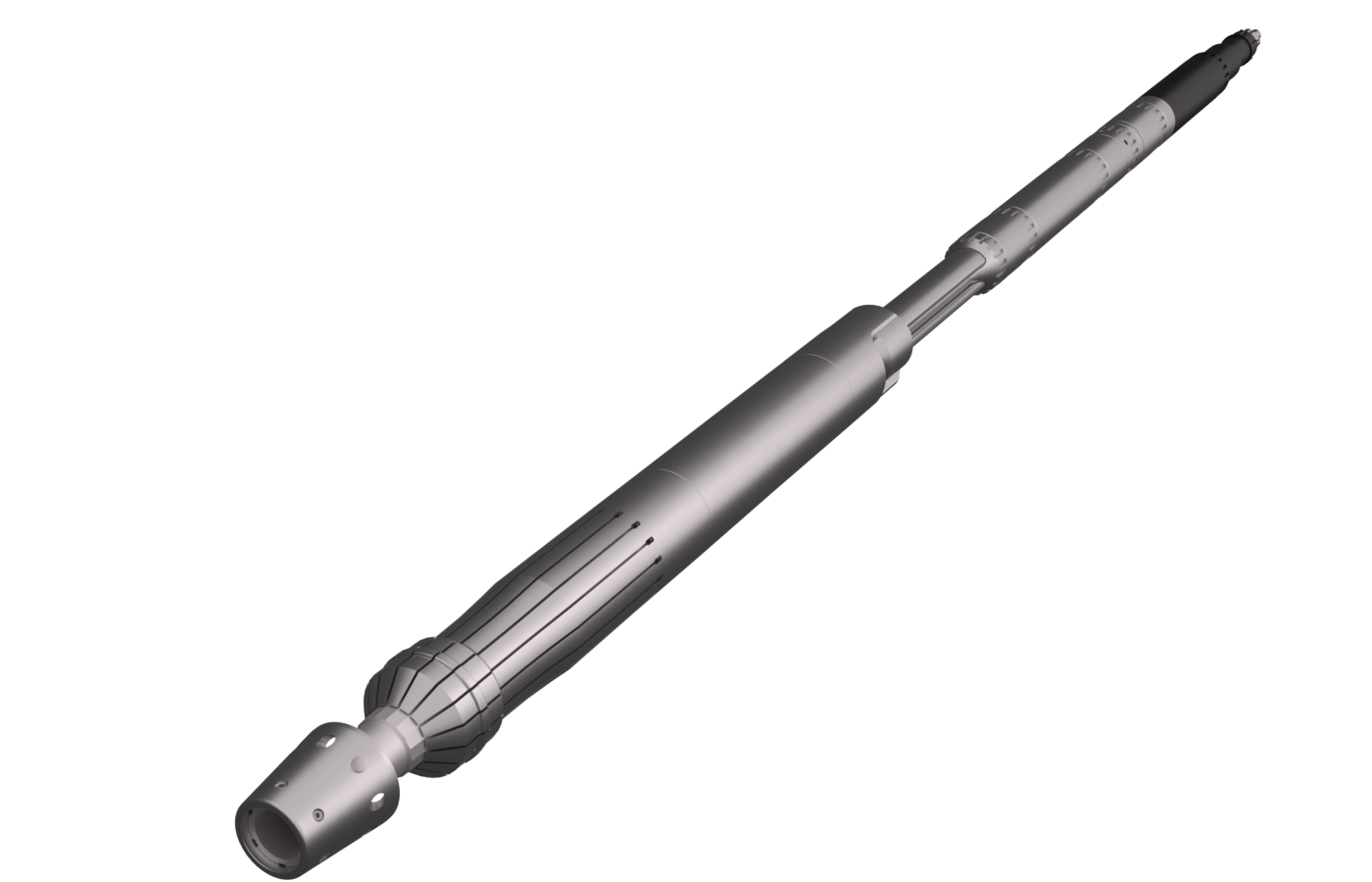

Mutliple tool configurations

Bringing high force linear actuation to the down hole market through the TorcDesperado's actuated mandrel, the user can connect any type of mechanically actuated tools to adress a multitude of well applications.

Do multiple operations in a single run:

- Radial Expansion Applications

- Punching/Perforating Tubing

- Opening Collapsed Tubulars

- Expanding dimples/standoff

- Local expansion for anchoring tubular plugs (Cement/Bismuth)

- Mitigating Micro Annulus

- Shifting and dimpling applications

- Lock/open Safety valves

Being reusable and mechanical, all tools are able to do multiple operations, like expansion or dimpling, in a single run and without the use of compressed gas or explosives. Change of extensions is intuitive, with a quick turn-over on the support vessels deck.

Available extensions:

TorcPuncher

the TorcPuncher is used to mechanically punch multiple holes in a tubular. The knifes on the TorcPuncher are axially acitvated by the EMT and TorcDesperado and travels relatively to a cone in order to push the knives through the tubular by taking the steel to the edge of their tensile strengt.

As a result of this, the knifes continue to deform the newly created holes, providing controllable standoffs between the tubing string and the annular host casting.

After the holes have been made and expanded to the desired diameter the tool is retracted and reposisioned for another expansion.

- Mechnical multiple punch tool; make multiple holes in same run

- Knives cutting through pipe

- 4 x holes with 360 degrees coverage

- Holes can be optimized upon request

- Removing at least 2% of the material

- Designed for Perforate, Wash and Cement Operations

TorcExpander

the TorcExpander is used to mechanically deform a collapsed tubular by swaging it open. The expansion segments on the TorcExpander can be engineered to fit the geometry of the collapsed in order to deform the tubular back towards it original shape.

After the deformation has been made and expanded to the desired diameter the tool is retracted and reposisioned for another expansion.

- Open collapsed tbg/csg

- Multiple heads available for various size of tubulars and collapse cross-section.

TorcStandoff

the TorcStandoff is used to mechanically deform a tubular by expanding a set of segments against the tubing wall. The expansion segments on the TorcStandoff are axially acitvated and travels relatively to a cone in order to deform the tubular.

By performing this type of expansion the TorcExpander provides a direct radial force relative to other industry solutions that provides both a radial and axial force component.

it also provides a controllable standoff between the tubing string and the annular host casting. After the expansion to the desired diameter, the tool is retracted and reposisioned for another expansion.

- Enables to expand tubing to increase and deform csg/tbg.

- 4,5” radial standoff

- No holes

Local Expansion Tool

- Punch and stand-off

- Local Expansion

- Collapse Expansion

- Shift and dimple

Custom / Tailor-made requirements and specifications can be accommodated.