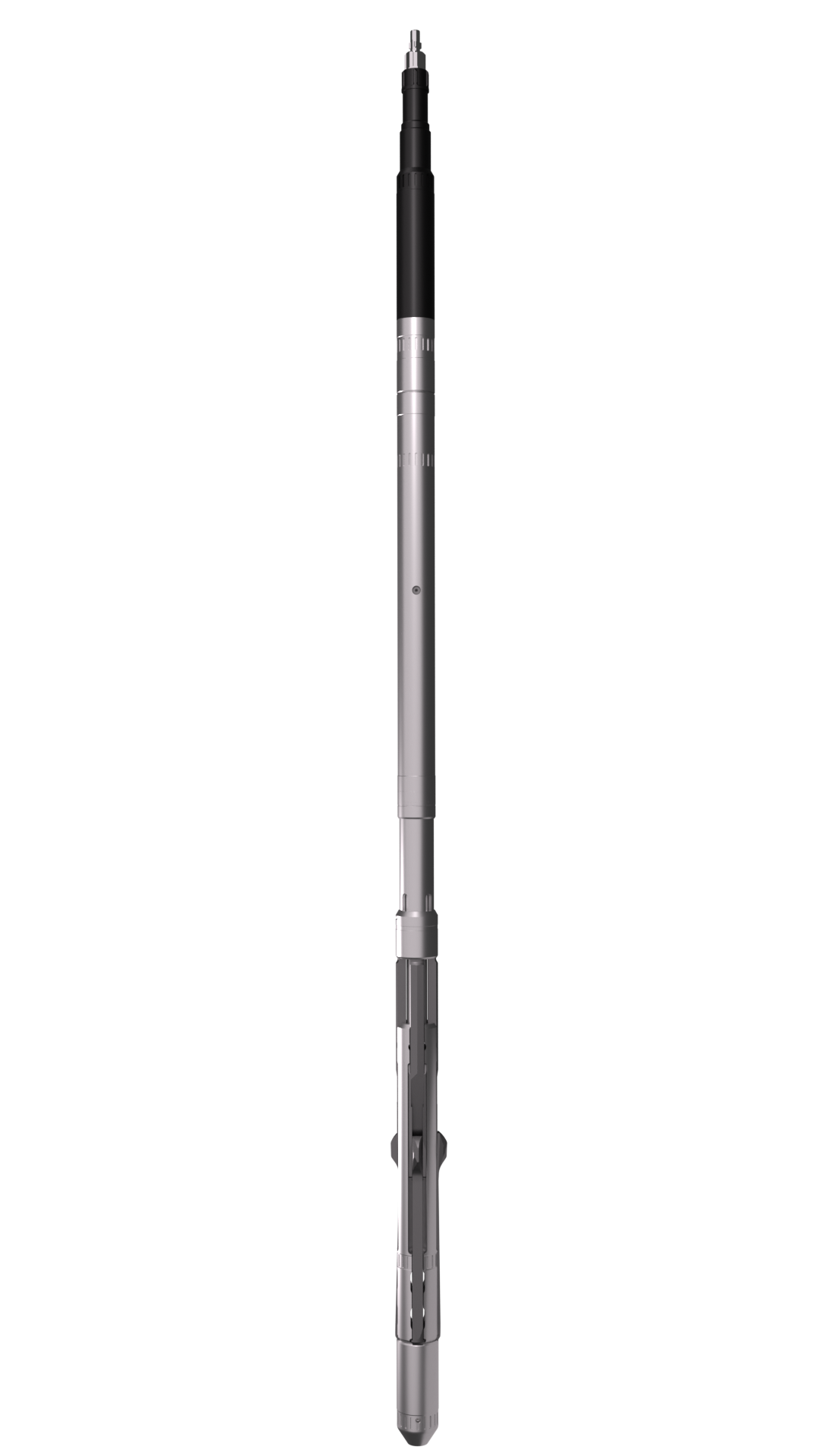

TorcPuncher

Non explosive mechanical perforating

Configured together with the TorcDesperado Linear Actuator and the Electric Manipulation Tool (EMT) the TorcPuncher is used to mechanically punch multiple holes in a tubular. The knifes on the TorcPuncher are axially acitvated by the EMT and TorcDesperado and travels relatively to a cone in order to push the knives through the tubular by taking the steel to tensile. As a result of this operation the knifes continue to deform the newly created holes which also provides a controllable standoff between the tubing string and the annular host casting. After the holes have been made and expanded to the desired diameter the tool is retracted and reposisioned for another expansion.

.jpg)

The engineered knives expand to engage the tubing wall

.jpg)

Tubing is taken to tensile by forcing the knives through.

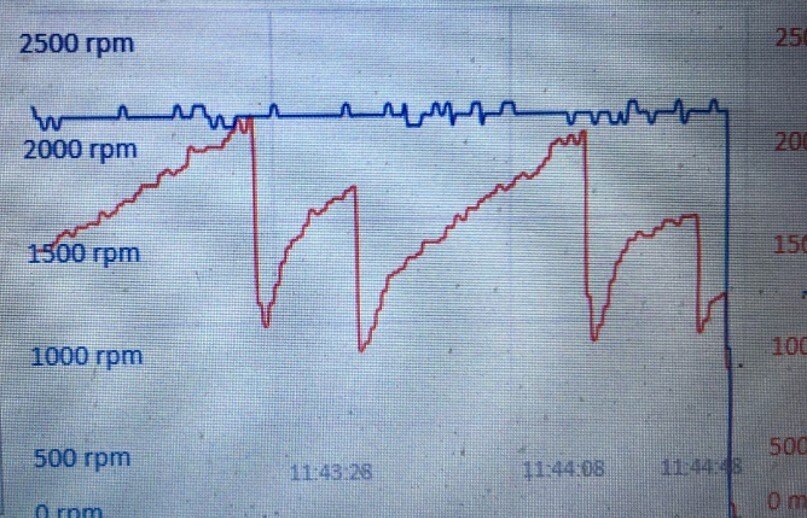

Real time verification of tubing punch is provided at surface.

Key features:

Features

- Rig Less Technology for Completion, Intervention & Plug & Abandonment

- Real time control through TorcDrive Software

- Signatures with real time verification of each punch

- Multiple Punches in the same run

- Mechanical retraction with positive verification

- Debris optimized tool geometry

- Eliminates the need for explosives

FAQ

What is the TorcPuncher used for?

The TorcPuncher is used to deploy one or more punch elements below stop collars to punch out a tubular using the Electric Manipulation Tool (EMT).

How is the TorcPuncher configured for different applications?

TorcPuncher is available in multiple configurations, allowing it to be adapted for various cutting needs, and it is activated and controlled by the EMT and TorcDrive system.

What role does EMT play in the use of TorcPuncher?

EMT provides control for deploying and activating the TorcPuncher during a run, enabling precise mechanical manipulation according to the configured punch elements.