Successful fishing of non-magnetic debris in a dry horizontal well bore.

Challenge

When a wellbore is filled with gas it is often in or prepared for its production phase. When foreign objects (fish) are found in the well bore at this stage it may not desirable to liquid fill the well in order to retrieve the fish, hence the options of retrieval are both challenging and limited. The most common approach in relation to retrieving objects left in a horizontal well bore would conventionally be considered to include magnets or venturi junk baskets when the object does not have a fish neck allowing the use of standard spears, pulling tools, and grapples. In the case where the fish is non-magnetic, this also further complicates the retrieval process.

Solution

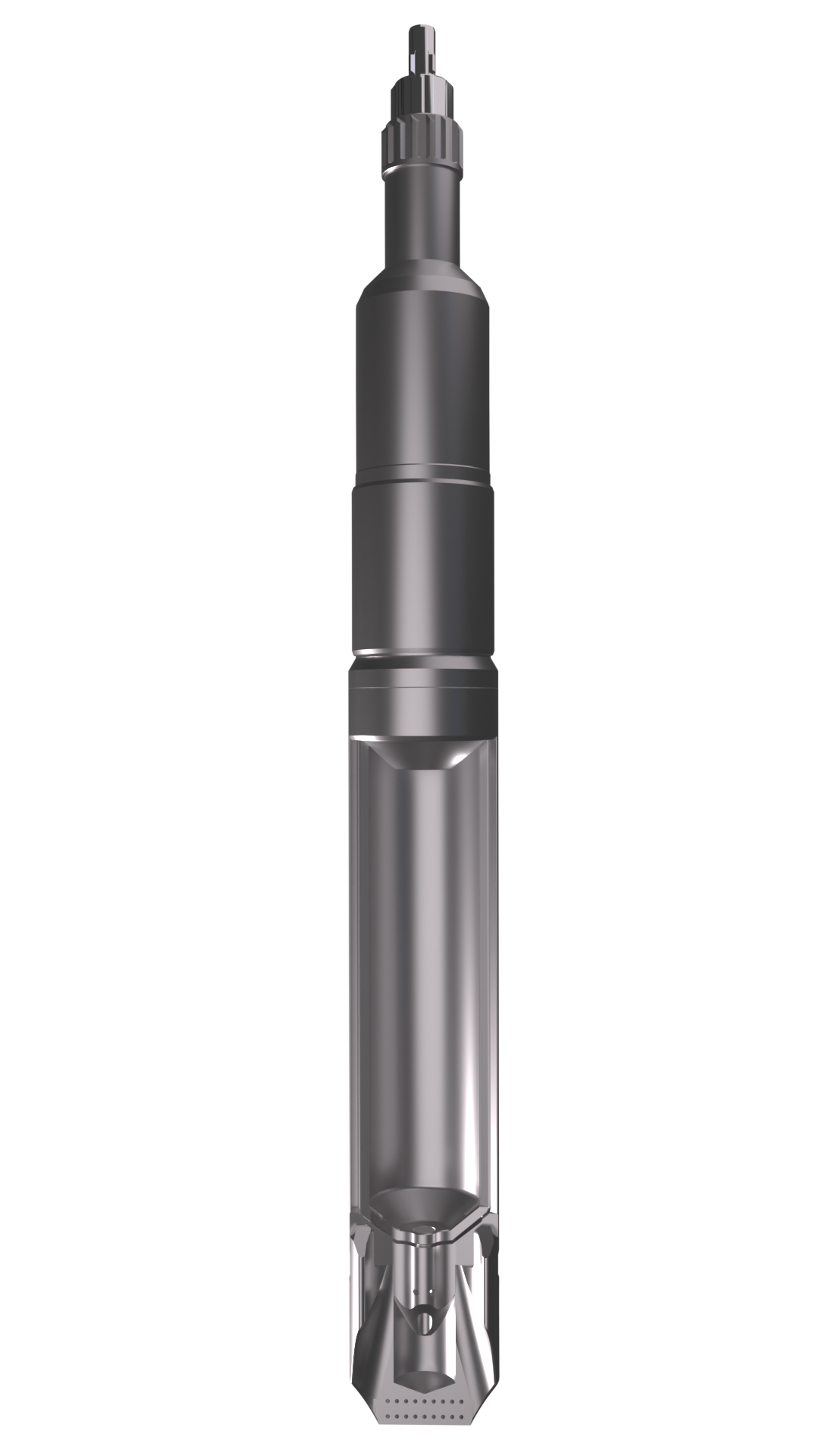

Applying the ability of the EMT to provide control of independent rotations and displacement using multiple manipulators enabled the creation of a collection tool that was able to be run into the well and collect the objects in a controlled manner. The application of rotation, coupled with real time sensor data supplied by the EMT, enabled the collection tool to be deployed on coiled tubing with electrical conductor. When the collection tool was situated above the fish it was opened up and oriented high side before being run in hole past the fish. Subsequently, rotation was applied in order for the collection tool to scoop up the fish into the tool which then was closed again. An internal manipulator was then actuated in order to verify that the tool had collected the fish as verified on the real time sensors on the EMT. The tool was retrieved to surface and opened up, containing 3 objects of interest.

A world’s first delivery successfully developed, produced, tested, and run in hole to retrieve the non-magnetic fish on the first run in a period of 3 months.

Value Created

- The debris where collected on the first run and retrieved to surface

- Customer stated that this operation saved them from a minimum of 5 days of subsequent fishing operations.

- It also regained access to the installed plug below and ensured that the isolated reservoir sections could be brought back into production.